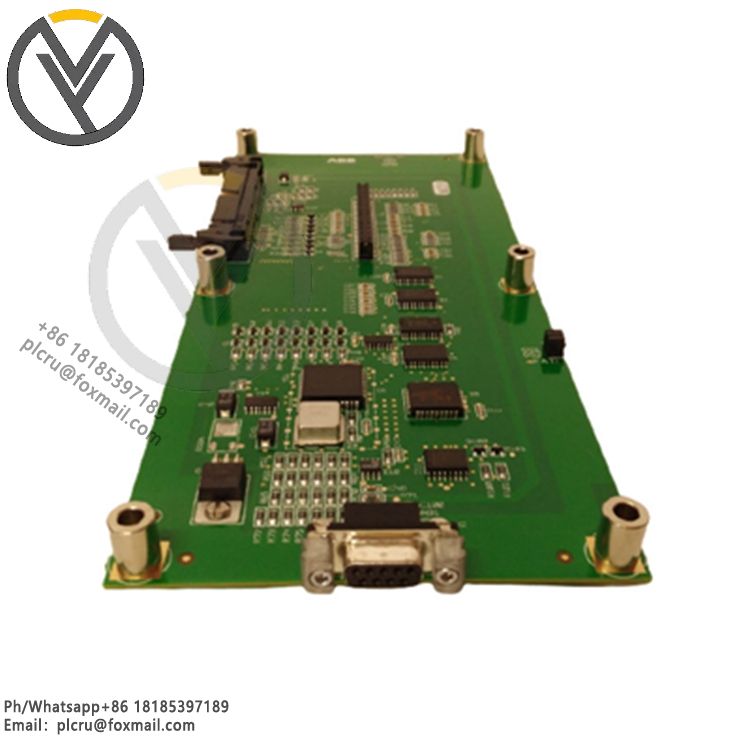

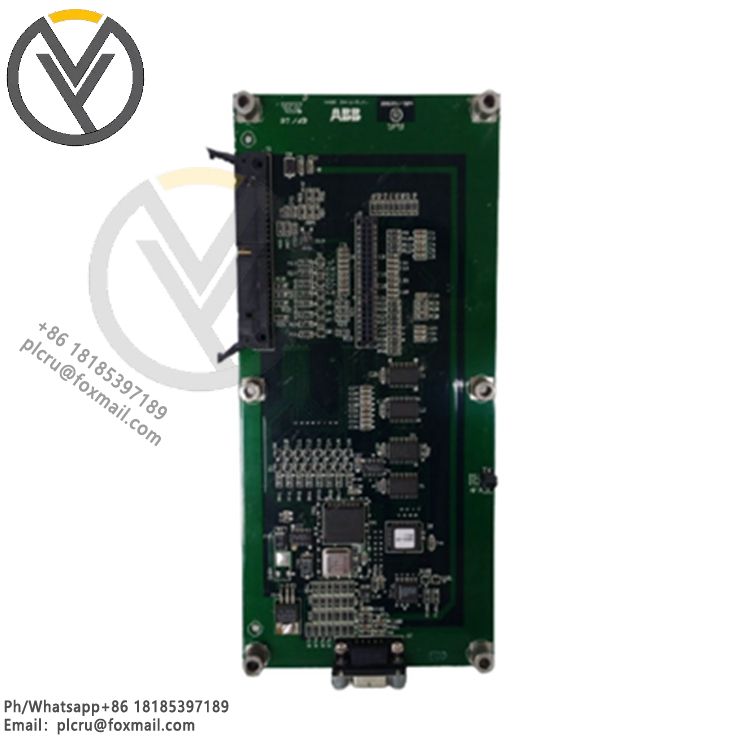

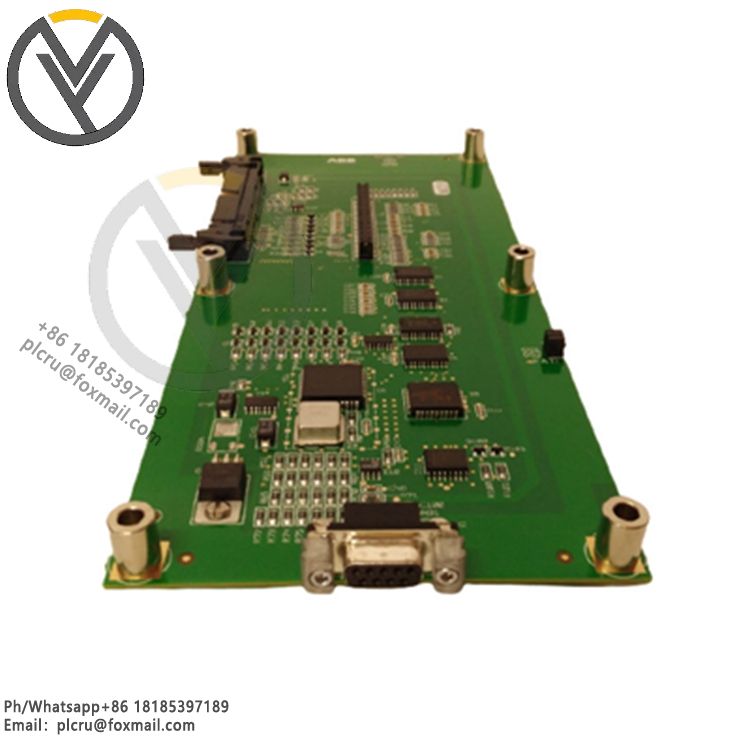

ABB PPC322BE1 HIEE300900R1 Controller

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The ABB PPC322BE1 HIEE300900R1 controller is a high-performance industrial autom

The ABB PPC322BE1 HIEE300900R1 controller is a high-performance industrial automation control device. The following is a detailed explanation of it:

Product Features:

High-performance processor: The controller is equipped with a high-performance processor that can handle complex control algorithms and tasks and provide fast response speed[1].

Multiple interfaces: Equipped with a variety of interfaces, such as Ethernet interface, serial interface and digital input/output interface, it is convenient to communicate and connect with other devices and systems[1].

Flexible scalability: Supports a variety of expansion modules and slots, and can be flexibly expanded and customized according to actual needs to adapt to different application scenarios[1].

Reliability and stability: ABB is a well-known automation technology supplier. Their products have been rigorously tested and verified, with reliability and stability, and can run for a long time in various industrial environments[1].

Powerful functions: It provides rich control functions and algorithms, supports real-time control and monitoring, and can realize complex automation control tasks[1].

Compatibility: Compatible with other ABB automation equipment and systems, and can be seamlessly integrated and collaborated with other modules and components[1].

Simplified maintenance and diagnostics: User-friendly maintenance and diagnostics functions are usually provided to help users troubleshoot and quickly repair, reducing downtime [1].

Application background:

Chrysler and Fiat CArS architecture: PPC322BE1 HIEE300900R1 is related to CArS (Control Architecture Standard) jointly defined by Chrysler and Fiat Manufacturing Engineering Committee. CArS architecture uses process simulation to improve design planning and implementation, aiming to reduce integration costs and improve production line efficiency and reliability [2].

Process standards for control integration: A major goal of the CArS architecture is to achieve flexible and simple control integration based on saving integration costs, improving MTBF (mean time between failures) and reducing MTTR (mean time to repair) [2].