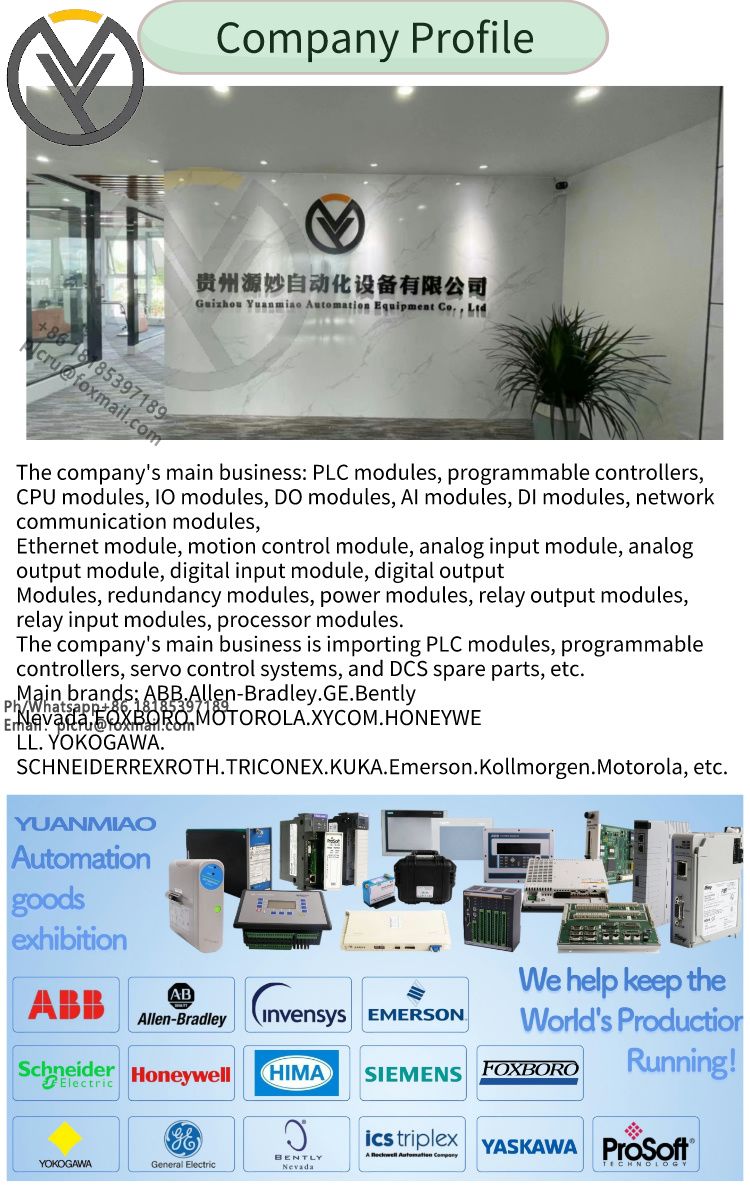

ABB SPASI23 Analog input module

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The ABB SPASI23 analog input module is a key component used in a wide range of i

The ABB SPASI23 analog input module is a key component used in a wide range of industrial automation systems to collect and monitor a wide range of analog signals such as temperature, pressure, flow, current and voltage. The following is a detailed introduction to the module:

1. Basic functions

Analog signal acquisition: The SPASI23 module can receive analog signals from various sensors and devices, such as temperature sensors, pressure sensors, etc.

High precision measurement: The module usually has high resolution and is able to accurately measure changes in the input signal, ensuring the accuracy of the data.

Multi-channel input: Modules typically have multiple input channels, each of which can be connected to an analog signal source, depending on the model and configuration of the module.

Second, technical characteristics

Signal sampling and conditioning:

Sampling: The module measures and records the analog signal at a certain time interval, and the sampling frequency determines the accuracy and response speed of the signal.

Conditioning: The sampled signal may contain noise and interference, and the module will be filtered, amplified, linearized and other processing to improve the quality and stability of the signal.

Communication interface: SPASI23 module supports a variety of communication protocols (such as Profibus, Modbus, etc.) to facilitate data transmission with other automation systems or controllers.

Easy integration: The module is easy to integrate into the automation system of ABB or other manufacturers to achieve seamless connection of data acquisition and control functions.

3. Application fields

The SPASI23 analog input module can be used in a wide variety of industrial control and monitoring applications, including but not limited to:

Process control: Used to monitor key parameters in the production process in chemical, petroleum, pharmaceutical and other industries.

Temperature monitoring: real-time monitoring of the temperature of equipment or the environment in metallurgy, power, food processing and other fields.

Pressure monitoring: In hydraulic and pneumatic systems, pressure changes are monitored to ensure stable operation of the system.

Flow control: During liquid or gas transportation, the flow is controlled to maintain the continuity of the production process.

![1[1].jpg](/uploads/allimg/20240412/1-240412102Q0I1.jpg)

Related products

ABB LTC745A101 3BHE039905R0101

ABB KUC720AE01 3BHB003431R0101

ABB UFC760BE1041 3BHE004573R1041

ABB UNITROL1000 B-Z V104 3BHE014557R6104