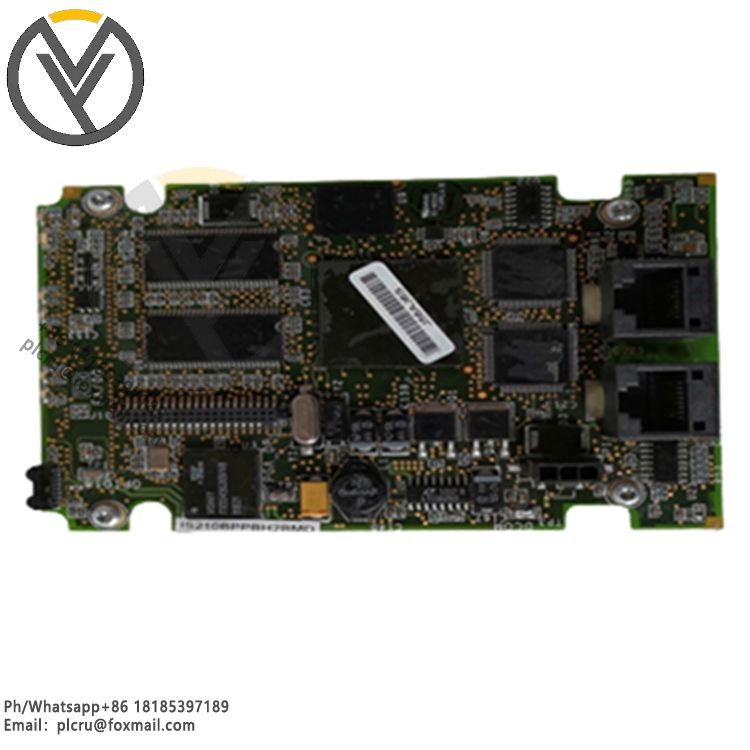

GE IS230TCATH1A gas turbine control system

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The GE IS230TCATH1A gas Turbine control system is a gas turbine control solution

The GE IS230TCATH1A gas Turbine control system is a gas turbine control solution from General Electric (GE). The system is highly flexible and reliable for a wide range of applications, including power generation, the oil and gas industry, aviation and industrial manufacturing. The following is a detailed introduction to the GE IS230TCATH1A gas turbine control system:

System overview:

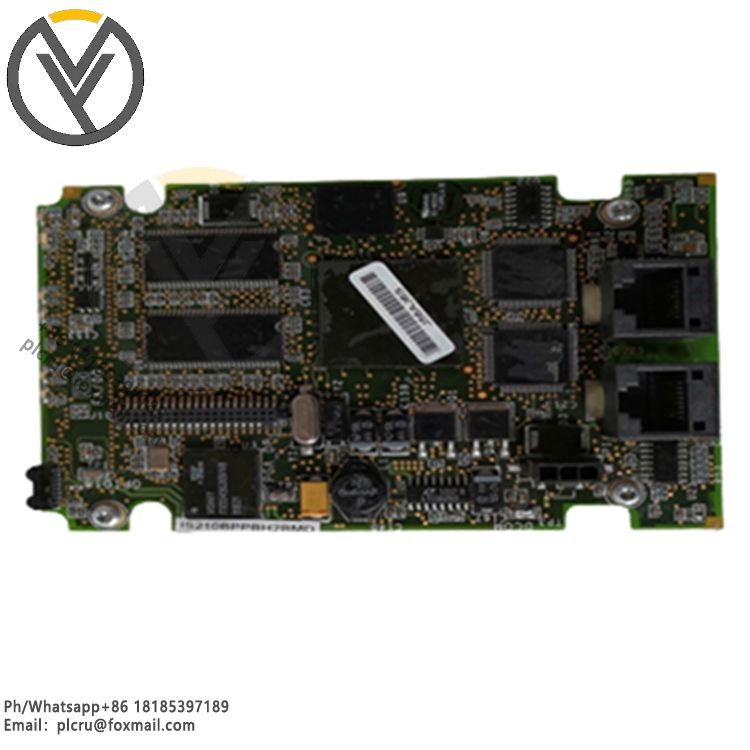

The GE IS230TCATH1A is a gas turbine control system with the Mark VIe control system at its core, which is a flexible platform that can be used for a variety of applications.

The system provides high-speed network input/output (I/O) capabilities for simplex, dual-redundancy, and triple-redundancy systems.

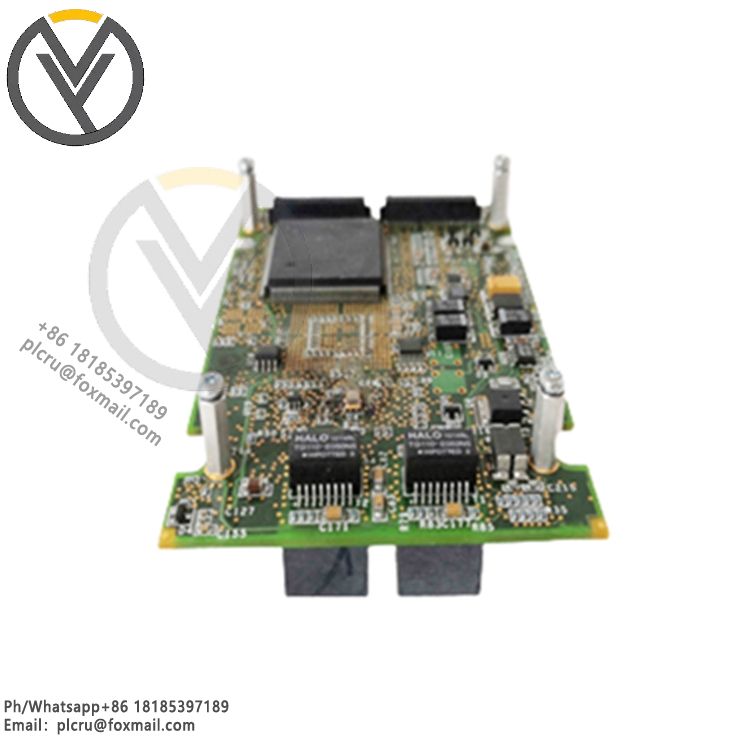

Industry standard Ethernet communication is used for I/O, controller, operator and maintenance station monitoring interfaces, and third-party systems.

Technical features:

High-speed network communication: 100 MB Ethernet is used to communicate with local and distributed I/O modules, ensuring real-time and efficient data transmission.

Redundant design: It can be used in non-redundant, dual redundant and triple redundant configurations to ensure high availability and fault tolerance of the system.

Real-time multitasking operating system: The IS230TCATH1A main processor and I/O module use a real-time multitasking operating system to ensure the timeliness and accuracy of the system response.

Control software: The control software is provided in a configurable control block language and stored in non-volatile memory for easy system configuration and maintenance.

Configuration and application:

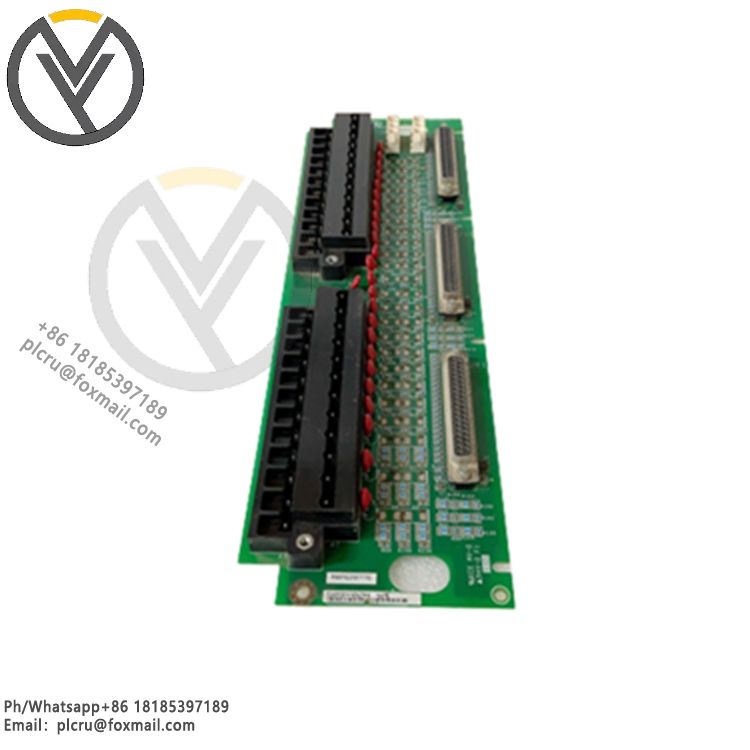

I/O module: The Mark VIe I/O module consists of a patch board, a patch board, and I/O packets, which can be added as needed to increase I/O capacity.

Communication interface: Support Ethernet network interface, as well as copper and optical fiber interface, to ensure that the system and other devices and systems communication unimpeded.

Application industry: Widely used in power plants, oil and gas industry, aviation and industrial manufacturing.