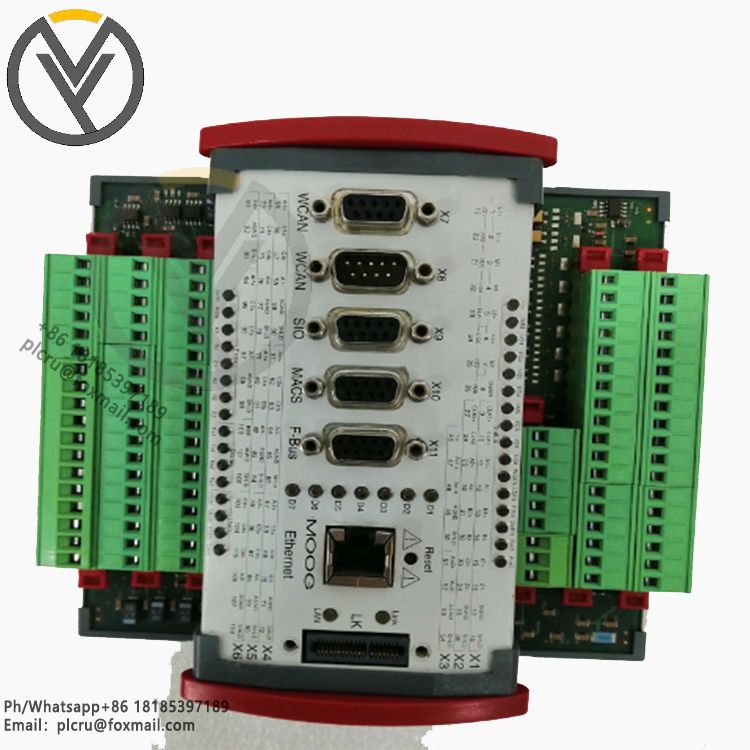

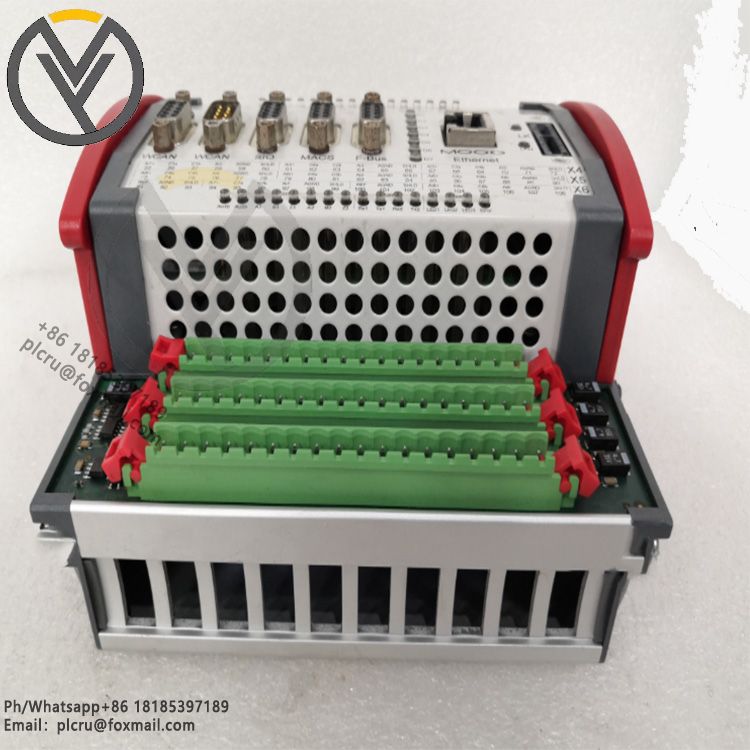

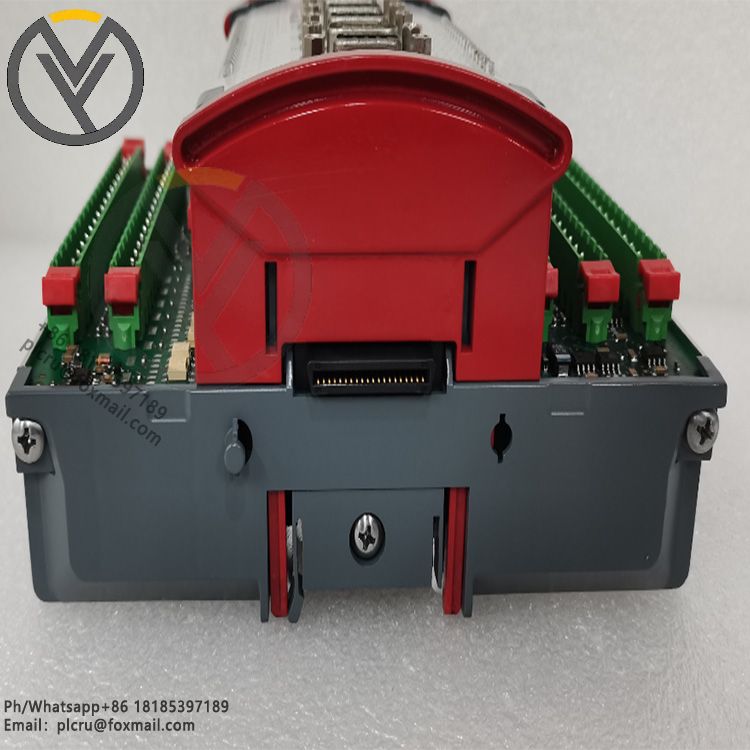

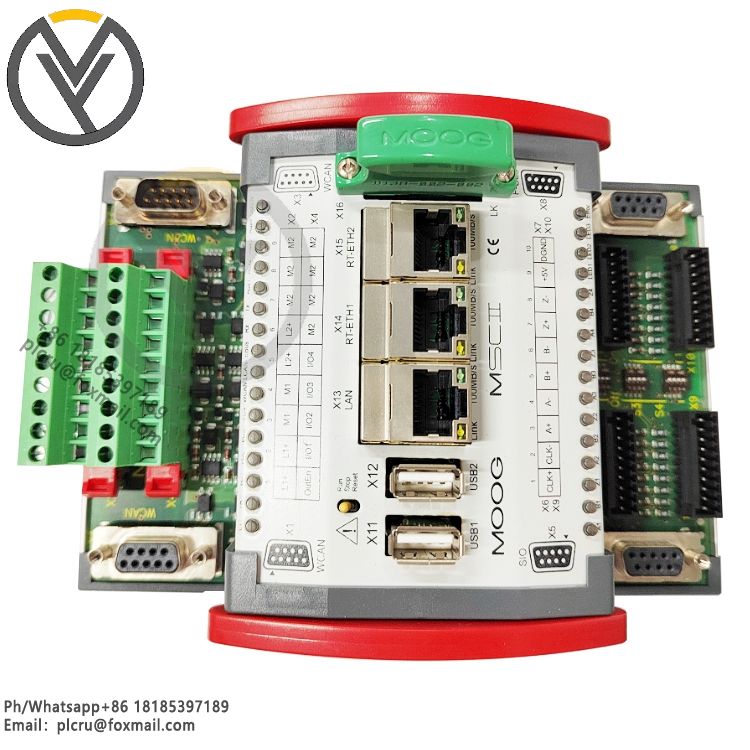

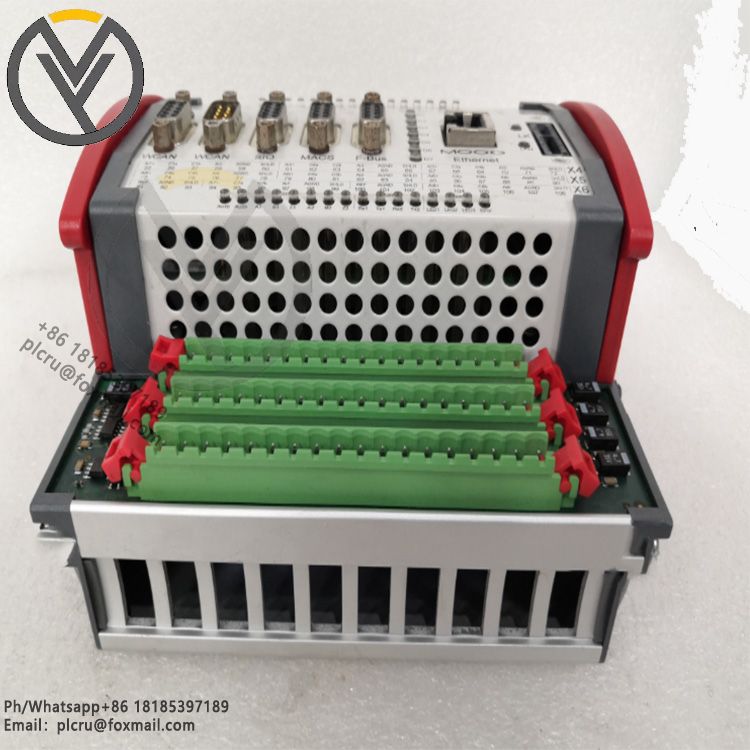

MOOG C633-0001-R02KO1M0VSE2 Servo Valve

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The MOOG C633-0001-R02KO1M0VSE2 servo valve is a high-performance servo control

The MOOG C633-0001-R02KO1M0VSE2 servo valve is a high-performance servo control valve produced by Moog. The following is some key information about this servo valve and possible problems and causes:

Main uses and features:

This servo valve is designed to provide precise control and response and is typically used in industrial applications that require high-precision fluid control, such as hydraulic systems, fuel systems, etc. [3].

Moog servo valves are generally highly reliable and durable and can operate under a variety of complex and harsh environmental conditions [3].

Common problems and causes:

The servo valve is not operating: Possible causes include broken wires or desoldering of the motor coil, and incorrect connection of the oil inlet or outlet [3].

With a fixed output but out of control: Possible causes include blockage of the front stage nozzle, foreign matter stuck in the valve core during maintenance, and deformation of the valve body [3].

Slow response or slow response: Possible causes include a drop in the system oil supply pressure, partial blockage of the maintenance filter, and excessive internal leakage of the actuator in the system [3].

Oil leakage: Possible causes include poor processing quality of valve seat, poor sealing performance, and problems with valve port sealing ring quality [3].

Maintenance and overhaul:

In order to effectively prevent automation instrument failures, appropriate instrument overhaul methods should be used, such as observation method, signal measurement method, and replacement method [4].

During maintenance, equipment such as a multimeter can be used to measure automation instruments to analyze potential failures [4].

Pay attention to lightning protection and anti-corrosion measures, because automation instruments are easily affected by external factors such as lightning and corrosive gases [4].