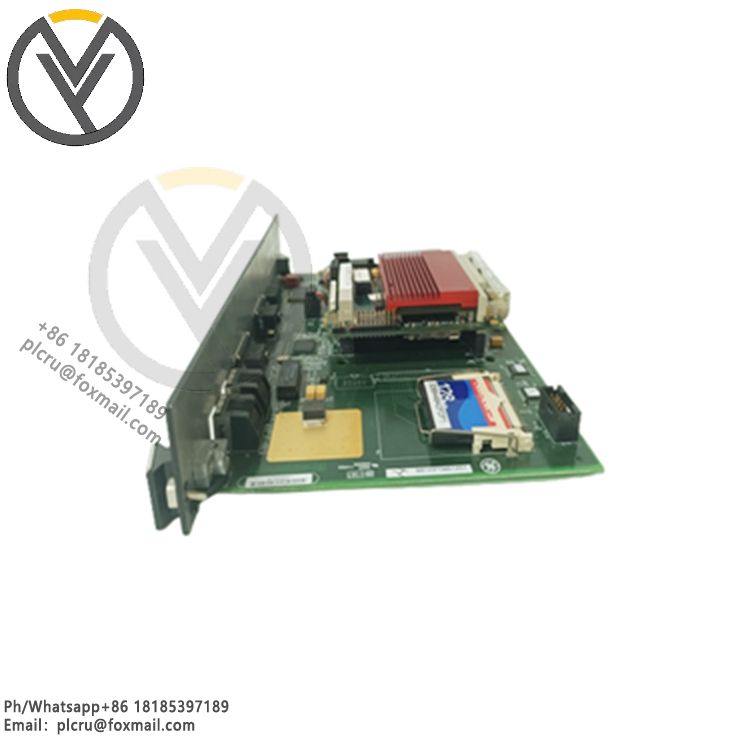

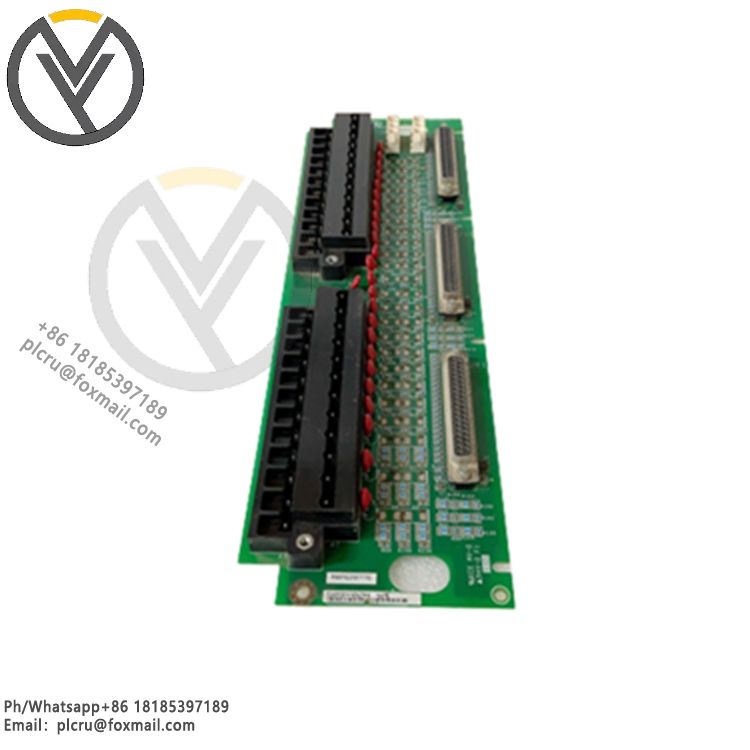

369-HI-0-M-0-0-0-E GE motor management relay

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The 369-HI-0-M-0-0-0-E GE Motor Management Relay is a high-performance motor pro

The 369-HI-0-M-0-0-0-E GE Motor Management Relay is a high-performance motor protection and control device manufactured by GE Multilin. Here are some details and features about this relay:

Functions and Applications:

Mainly used for motor protection, including over current, over load, short circuit, phase sequence, overheating and other protective functions to prevent motor damage due to failure.

The operating parameters of the motor, such as current, voltage, power factor and speed, can be monitored to evaluate the performance and efficiency of the motor.

It usually has control functions for starting, stopping, and reversing the motor, and supports multiple modes of operation [3].

It may be equipped with a condition monitoring function, which can monitor parameters such as the operating state and temperature of the motor and trigger alarms or operations when needed [3].

Some models may have a communication interface to transmit motor status data to a monitoring system or upper control system. [3]

Product parameters:

Input voltage range: 12-48VDC[2].

Output voltage range: 5VDC[2].

Output current: Maximum 10A[2].

Efficiency: greater than 90%[2].

Dimensions: 170mm x 105mm x 32mm[2].

Weight: about 120g[2].

Operating temperature: -20°C to +50°C[2].

Storage temperature: -40°C to +70°C[2].

Ambient humidity: 5% to 95% relative humidity (no condensation) [2].

CPU: 32-bit RISC processor [2].

Features:

The relay can "learn" individual motor parameters and adjust them for specific applications [4].

To improve the protection of the relay, the user can adjust the motor surge current, cooling rate, and/or acceleration time [4].

Some models may be equipped with temperature sensors to monitor the temperature inside and outside the motor, as well as early warning of temperature increases [6].

Relays are often able to record events and alarms during motor operation for subsequent analysis and troubleshooting [6].

Communication and interface:

Some models may have a Modbus/TCP protocol interface.