GE IS200AEPAH1AFD+IS210BPPBH2CAA Printed Circuit Board Mark VI

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The GE IS200AEPAH1AFD+IS210BPPBH2CAA are printed circuit boards (PCBs) used in G

The GE IS200AEPAH1AFD+IS210BPPBH2CAA are printed circuit boards (PCBs) used in GE Mark VI turbine control systems, part of GE's Speedtronic series for gas/steam turbine management.

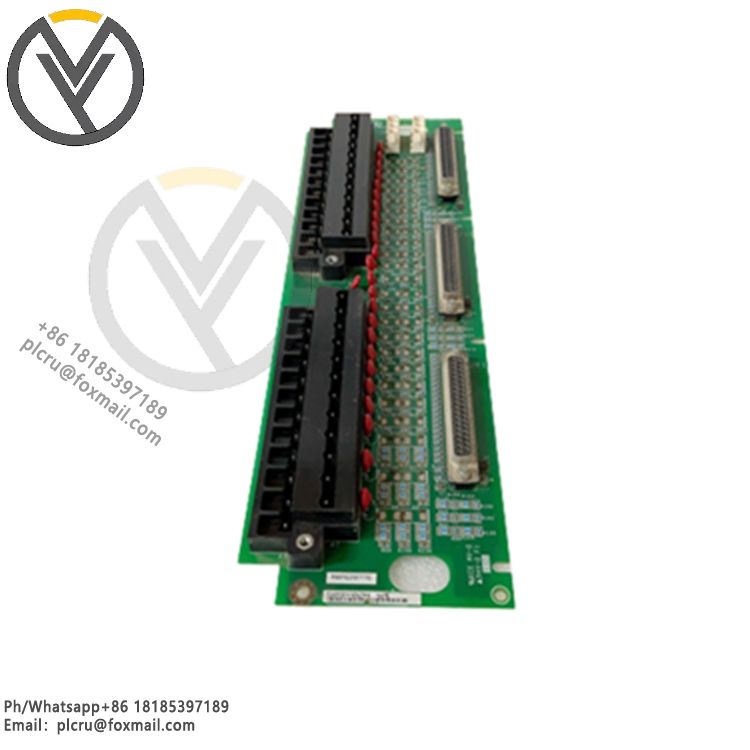

IS200AEPAH1AFD – Exciter Application Processor (EAP) Board

Function:

Acts as an Exciter Application Processor in the Mark VI system.

Manages generator excitation control, including voltage regulation, field current control, and protection.

Interfaces with thyristor bridges, field flash systems, and protection circuits.

Key Features:

Dual-channel redundancy (often used in pairs for reliability).

High-speed DSP (Digital Signal Processor) for real-time control.

Supports GE’s EX2100 excitation control (compatible with Mark VI).

Communicates via Ethernet, serial, or I/O modules within the turbine control system.

Typical Applications:

Gas turbine (Frame 5/6/7/9) and steam turbine excitation systems.

Power generation plants requiring precise voltage/frequency control.

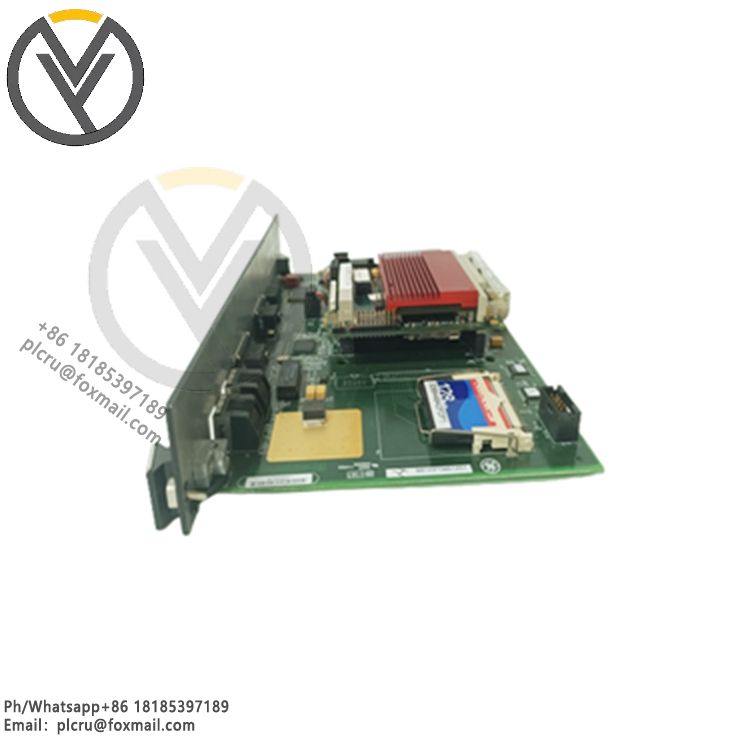

IS210BPPBH2CAA – Backup Protection Processor (BPP) Board

Function:

Serves as a Backup Protection Processor in the Mark VI system.

Provides redundant protection for critical turbine/generator functions (overspeed, overvoltage, etc.).

Works alongside the Primary Protection Processor (PPP) for fail-safe operation.

Key Features:

Triple modular redundancy (TMR) support for high reliability.

Independent fault detection (compares with PPP for discrepancies).

Hardware-based trip logic for fast shutdowns in emergencies.

Communicates with I/O packs (e.g., IS200 series) via backplane.

Typical Applications:

Emergency turbine shutdowns (mechanical/hydraulic overspeed).

Generator protection (differential current, ground faults).

Common Mark VI System Integration

Both boards are rack-mounted in a Mark VI controller (VME or UR chassis).

Interfaces:

Ethernet (TCP/IP) for HMI/Workstation communication.

PROFIBUS/Modbus for field devices.

Hardwired I/O for sensors/actuators.

Software:

Configured via GE ToolboxST (for Mark VI).

Logic programmed in Cimplicity or Function Block Diagrams (FBD).

Related Products: